Lightning: the not-so-silent borehole pump killer

/We have all seen these flashes and then waited for the bang that follows. Count the seconds between the flash and the sound arriving and divide by 3 to get the kilometres to the site of the strike. Did that bolt of energy of hundreds of millions of volts, tens of thousands of amps and up to 5 times hotter than the surface of the sun end up in the controls of the traffic light that is between you and your office? More seriously, did it end up, through some unfortunate rule of physics, in your borehole pump sitting in the water in the ground? This could turn out to be the source of a lot of frustration and expense.

But electrical surges caused by lightning strikes need not mean the end of your borehole installation. This article will outline some of the ways in which damage to borehole pumps and motors, and all the equipment in a borehole installation, can be prevented. But let’s start with looking at the lightning itself.

How lightning causes failures

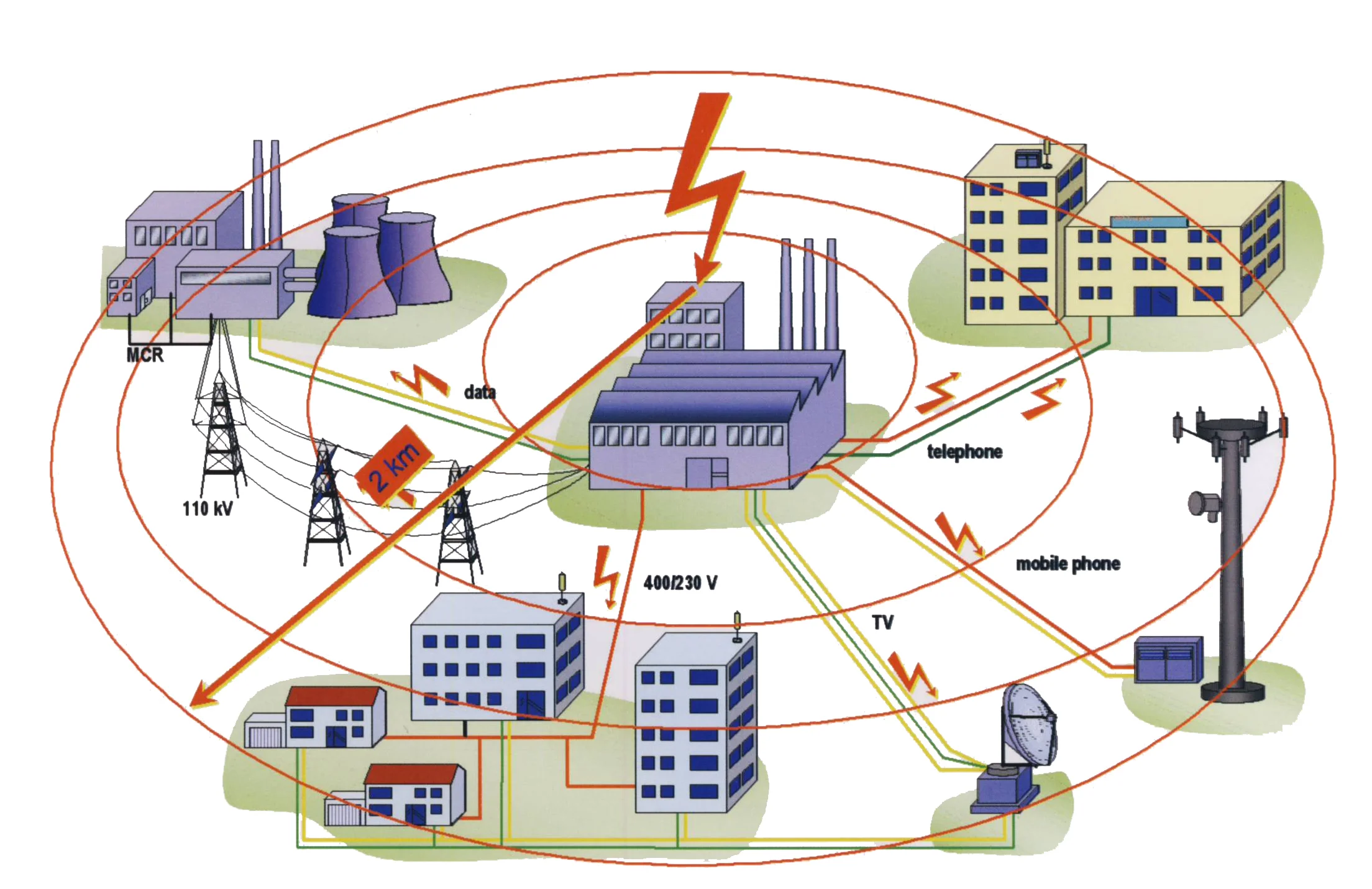

Imagine standing next to a river and throwing a large stone into the water. The resulting splash morphs into a number of circular ripples that spread out concentrically from the point of impact. These ripples represent energy derived from the stone falling through the air and colliding with the water. In the case of lightning, the energy from the bolt impacts the ground and spreads out, also in concentric circles, as magnetic lines of force.

Figure 1: Concentric lines of magnetic force resulting from a lightning strike. (Surge Technologies, Johannesburg)

In high school science we were told that if a conductor is exposed to magnetic lines of force that are time dependent, then an electrical current will be induced in the conductor. Consider the fact that the earth beneath our houses and buildings is a labyrinth of wires and cables that support our electricity, telephone and data needs (Figure 1) and it becomes apparent that these conductors lie in the path of any magnetic pulse.

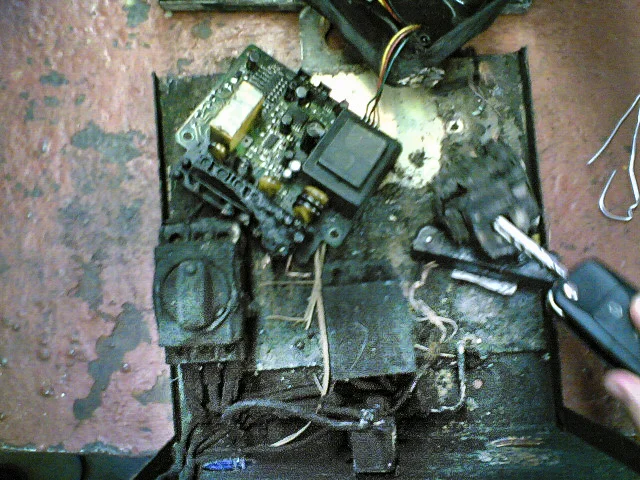

What are the possible values of the energy that can be induced in these cables? The lightning experts say tens to hundreds of thousands of volts and thousands of amps are common. The printed circuit boards of the controllers for borehole pumps (and those faulty traffic lights!) operate on voltages of about 5V. The pump’s motor operates on 230V or 400V, or other voltages that are way below the range that a lightning strike can induce in a conductor. The windings in a motor have a thin layer of varnish which is used to contain the current. Not what can be expected to hold onto many thousands of volts and amps.

Figure 2: Spikes, swells and sags that arrive in your electrical system.

Figure 3: This could, quite possibly, be the end result. This one killed 6 control boxes and pump motors, a large transformer and many metres of cable.

Preventing damage in borehole installations

Having induced this huge spike in the supply, how can it be safely disposed of? Enter the “electrical safety valve” or surge arrestor. Essentially, under normal operating conditions, this component resists/blocks the flow of electricity. If the voltage rises above a set level it allows flow, usually to earth, which is what the original lightning bolt was looking for anyway.

In order to guard our equipment against this onslaught, we set up distinct lines of defence, almost like the trenches in a battle. Our first line is the arrestors fitted to the high voltage lines coming in from the service provider.

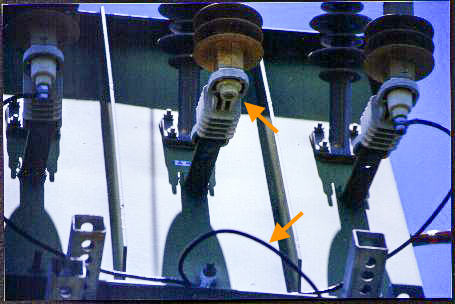

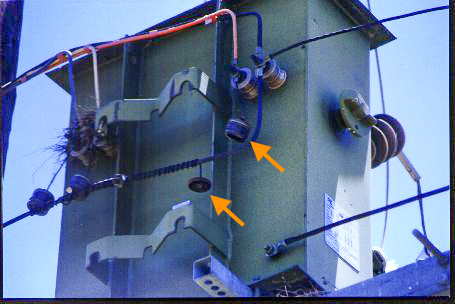

Figure 4: Medium voltage arrestor failure, transformer primary side

Figure 5: Two halves of an arrestor blown apart on the secondary side of the same transformer.

Figures 4 & 5 show a transformer on a farm in the Standerton area. The surge that caused this must have been a substantial one to have damaged the arrestors on both sides of the transformer (defence line 1) and then destroyed the pump controller/protection device (defence line 2). This was the third controller to have failed within a year.

Fortunately, the really expensive part of the installation, namely the motor connected to the submersible pump in the borehole had survived. So essentially, defence line 1 (the transformer arrestors) and defence line 2 (the pump controller), had been breached. The motor was living on borrowed time!

A plan of action was implemented:

- The transformer was replaced with a service exchange unit

- New, upgraded arrestors were fitted to the transformer

- New, upgraded arrestors were fitted to the pump’s electrical control box

- Earth connections were revamped.

Attributes of good surge protection

So what can be done to protect the equipment in your borehole installation?

Set up lines of defence

This includes high- and medium-voltage lines that are usually the responsibility of the service provider(s). The end-user would do well however, to do some basic monitoring of visible arrestors at the supply entry point. The end-user, through his/her qualified electrician, is responsible for the last line of defence in the low voltage circuit, i.e. from the transformer to the motor.

Use good quality equipment

Figure 6: Good quality arrestors being fitted to a control panel. Note the green condition indicators next to the electrician’s thumb.

Like anything else, there are high-end units and there are ones that will possibly handle a few minor surges before failing. When deciding on a unit, consider the implications of failure for your particular circumstances. Downtime in a borehole pump installation means not only repair costs, but loss of access to water, the inconvenience of having to remove the pump and rising main, replacing/repairing the motor, and then carrying out the re-installation process. Arrestors with indicators, selected and rated for the anticipated loads are essential.

Arrestor installation relative to the motor

Arrestors MUST be installed as close to the motor as possible. If the control panel is situated further than 10m from the top of the borehole, an additional weather-proof box, with isolator and arrestors must be installed close to the top of the borehole.

Cable sizes must be appropriate and should be as short as possible

Manufacturers recommend an earth cable at least one size larger than those carrying the current to the motor. Shorter cables mean, amongst other advantages, less chance of a damaging level of surge being induced.

The arrestors must be correctly earthed

Connecting the surge arrestors to an earth spike or rod in the ground is of minimal value, due to the resistance between the rod and the surrounding ground.

The earth terminals of the arrestors and water strata must be connected by a cable at least one size larger than the current carrying conductors. The earth wire must, preferably, run from the surge arrestors to the shell of the motor.

Connecting the surge arrestors to an earth spike or rod in the ground is of minimal value, due to the resistance between the rod and the surrounding ground. If the rising main is metallic, then the surge arrestors can be earthed to these pipes, in addition to the separate earth wire.

These requirements are in addition to all applicable national and regional codes for electrical wiring.

A word of warning here. Water in boreholes in quite a few parts of the country can be very aggressive and will attack and destroy exposed copper wire. It is recommended that insulated earth wire is used in the borehole with a sealed stainless steel terminal for attachment to the motor.

Arrestors require maintenance

A common mistake is to assume that once arrestors have been installed they will last the life time of the pump and motor unit. This assumption will most certainly lead to repeated premature failure of the installation. Check the arrestors on a regular basis especially after thunderstorms or if the region has experienced a high number of power failures.

I’m sure there are many lightning-related war stories that you can share. Do you have any tips or suggestions for managing lightning and over-voltage in borehole installations? Please share your views in the comments.

John Tonkin is the editor of the Journal and offers training and advisory services at John Tonkin and Associates. His areas of specialism include pumps, pipes and valves within the system as a whole.